Custom 1” to 6” 45 Degree 304 Stainless Steel Exhaust Pipes Elbow Mandrel Bends

Pipe fittings that change the direction of the pipeline The main difference between stainless steel elbows and carbon steel elbows is the material. The chemical composition contained in them will keep the surface of the elbow from rusting and corroding for a long time. In the pipeline system, elbows are pipe fittings that change the direction of the pipeline. According to the angle, there are three most commonly used ones: 45°, 90°, and 180°. In addition, according to the needs of the project, there are also other abnormal angle elbows such as 60°.

Product Introduction

An elbow is a pipe fitting used to change the direction of a pipe. It is usually used in piping systems where turns or changes in flow direction are required.

| Product Name | Elbow |

| Size | 1/2″-36″ seamless, 26″-110″ welded |

| Standard | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, etc. |

| Wall thickness | STD, XS, XXS, SCH20,SCH30,SCH40, SCH60, SCH80, SCH160, XXS and etc. |

| Elbow | 30° 45° 60° 90° 180°,etc |

| Radius | LR/long radius/R=1.5D,SR/Shrot radius/R=1D |

| End | Bevel end/BE/buttweld |

| Surface | nature color, varnished, black painting, anti-rust oil etc. |

| Material | Carbon steel: A234WPB, A420 WPL6 St37,St45, E24, A42CP, 16Mn, Q345, P245GH,P235GH, P265GH, P280GH, P295GH, P355GH etc. |

| Pipeline steel: ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65,WPHY70, WPHY80 and etc. | |

| Cr-Mo alloy steel: A234 WP11,WP22,WP5,WP9,WP91, 10CrMo9-10, 16Mo3 etc. | |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant;ship building; water treatment, etc. |

| Advantages | ready stock,faster delivery time;available in all sizes,customized;high quality |

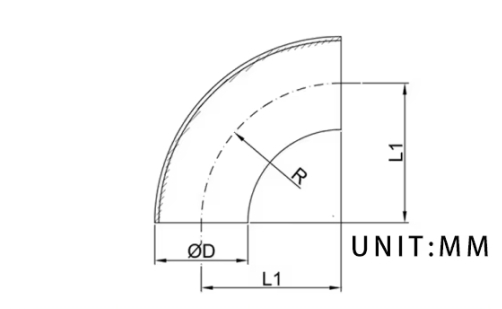

Product Specifications

Size (Inch) | D | L2 | Thickness |

19(3/4”) | 19 | 28.5 | 1.5 |

25(1”) | 25 | 33.5 | 1.5 |

32(1 1/4”) | 32 | 38 | 1.5 |

38(1 1/2″) | 38 | 48 | 1.5 |

45(1 3/4″) | 45 | 57.5 | 1.5 |

51(2”) | 51 | 61.5 | 1.5 |

57(2 1/4”) | 53 | 68.5 | 2 |

63(2 1/2”) | 63 | 78.5 | 2 |

76(3”) | 76 | 91 | 2 |

89(3 1/2”) | 89 | 101.5 | 2 |

102(4”) | 102 | 124 | 2 |

108(4 1/4”) | 108 | 131 | 2 |

114(4 1/2”) | 114 | 147 | 2 |

133(5 1/4″) | 133 | 169.5 | 2 |

159(6 1/4”) | 159 | 189.5 | 2 |

219 (8 1/2”) | 219 | 260.5 | 2 |

273(10 3/4”) | 273 | 353.5 | 2 |

325(12 3/4”) | 325 | 432 | 2 |

| Product Details | Product Production | Product Warehouse |

|  |  |

|  |  |

Applications

Product Packaging

Product Transportation